Automation Research & Embedded Technologies

Certificate Verification

Automation Research & Embedded Technologies

Certificate Verification

Automation Research & Embedded Technologies

Certificate Verification

Automation Research & Embedded Technologies

Certificate Verification

"Siemens and Mitsubishi Electric are among the leading PLC manufacturers globally.

ARET provides comprehensive PLC programming courses, designed to equip automation engineers with essential skills in PLC programming, understanding industrial networks, and familiarization with various PLC products and software."

Course Title:

Industrial-Based PLC Training (Siemens s7-200 and Mitsubishi FX3u)

Course Duration:

30 Days

Total No. of seats:

10 seats

Prerequisites:

Basic understanding of electrical systems, automation, and control systems.

Course Fee: BDT 4500.00

Industrial-Based PLC Training(Siemens s7-200 and Mitsubishi FX3u) 30-Day Course Syllabus:

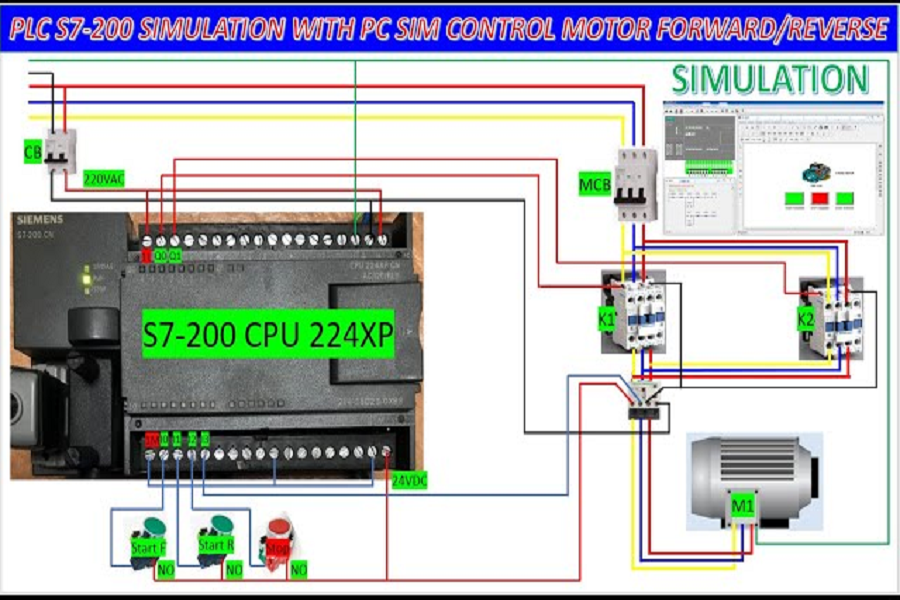

Day 1: Introduction to PLC Systems and Industrial Automation Theory: - Overview of PLCs, their role in industrial automation - Comparison of PLCs vs. traditional relay systems Practical: - Introduction to Siemens S7-200 and Mitsubishi FX3U PLCs - Setting up the hardware Day 2: PLC Architecture and Basic Components Theory: - Understanding PLC components: CPU, power supply, I/O modules, communication modules - PLC system architecture and memory organization Practical: - Identifying hardware components on Siemens S7-200 and Mitsubishi FX3U PLCs Day 3: Introduction to PLC Programming Theory: - Basics of PLC programming (Ladder Logic, FBD, STL) - Differences between Siemens and Mitsubishi PLC programming Practical: - Setting up and configuring the programming environment (Siemens STEP 7 Micro/WIN and Mitsubishi GX Works3) Day 4: Basic Ladder Logic Programming Theory: - Introduction to Ladder Diagram (LD) programming language - Logical operations (AND, OR, NOT) Practical: - Writing and testing simple ladder logic programs on Siemens S7-200 and Mitsubishi FX3U Day 5: Timers and Counters in PLCs Theory: - Understanding the role of timers and counters in automation - Types of timers (On-delay, Off-delay, Retentive timers) Practical: - Implementing timers and counters in Siemens S7-200 and Mitsubishi FX3U PLCs Day 6: Digital and Analog I/O Modules Theory: - Difference between digital and analog signals - Configuration and wiring of digital/analog I/O modules Practical: - Interfacing sensors and actuators with PLCs Day 7: Data Handling and Memory Management Theory: - Data types, registers, and memory areas in Siemens and Mitsubishi PLCs - Understanding data handling and storage in PLCs Practical: - Using data registers for storing and retrieving values in Siemens S7-200 and Mitsubishi FX3U Day 8: Advanced Programming with Functions and Subroutines Theory: - Creating and using functions and subroutines in PLC programming - Modular programming for complex tasks Practical: - Writing programs with subroutines and functions in Siemens and Mitsubishi PLCs Day 9: HMI Integration with PLCs Theory: - Introduction to Human-Machine Interfaces (HMIs) - Role of HMI in industrial automation Practical: - Interfacing Siemens S7-200 and Mitsubishi FX3U with HMI (basic screen design) Day 10: Communication Protocols (Modbus, Profibus, Ethernet) Theory: - Overview of communication protocols used in industrial automation - Setting up communication between PLC and other devices Practical: - Configuring PLC communication (Modbus, Profibus, Ethernet) for Siemens S7-200 and Mitsubishi FX3U Day 11: PLC Networking and Remote Access Theory: - PLC networking basics and remote control - Industrial Ethernet and SCADA integration Practical: - Creating a basic PLC network and remote access setup Day 12: Troubleshooting and Diagnostics Theory: - Common PLC troubleshooting techniques - Diagnostic tools and error handling in Siemens and Mitsubishi PLCs Practical: - Debugging programs and handling faults in real-time systems Day 13: PID Control and Process Automation Theory: - Introduction to PID (Proportional-Integral-Derivative) control - Applications of PID in industrial process control Practical: - Implementing PID control loops in Siemens S7-200 and Mitsubishi FX3U Day 14: Real-World Industrial Automation Projects Theory: - Case studies of industrial automation projects using PLCs - Design and control of automation processes Practical: - Building an industrial automation project (e.g., conveyor belt control, motor speed control) Day 15: Final Project Development and Presentation Theory: - Project planning and design in industrial automation Practical: - Developing and demonstrating a complete PLC-based automation project using Siemens S7-200 or Mitsubishi FX3U * Certification of course completion.Get the certificate